Reflecting on the tenets that shape our educational practices is fundamental for …

3-D Printing Technology Could Revolutionize Basketball Manufacturing

Carlos Changemaker

For nearly 150 years, basketballs have been dribbled and shot across courts. Despite their long history, the appearance and feel of these balls have remained largely unchanged. However, a new revolution could be on the horizon.

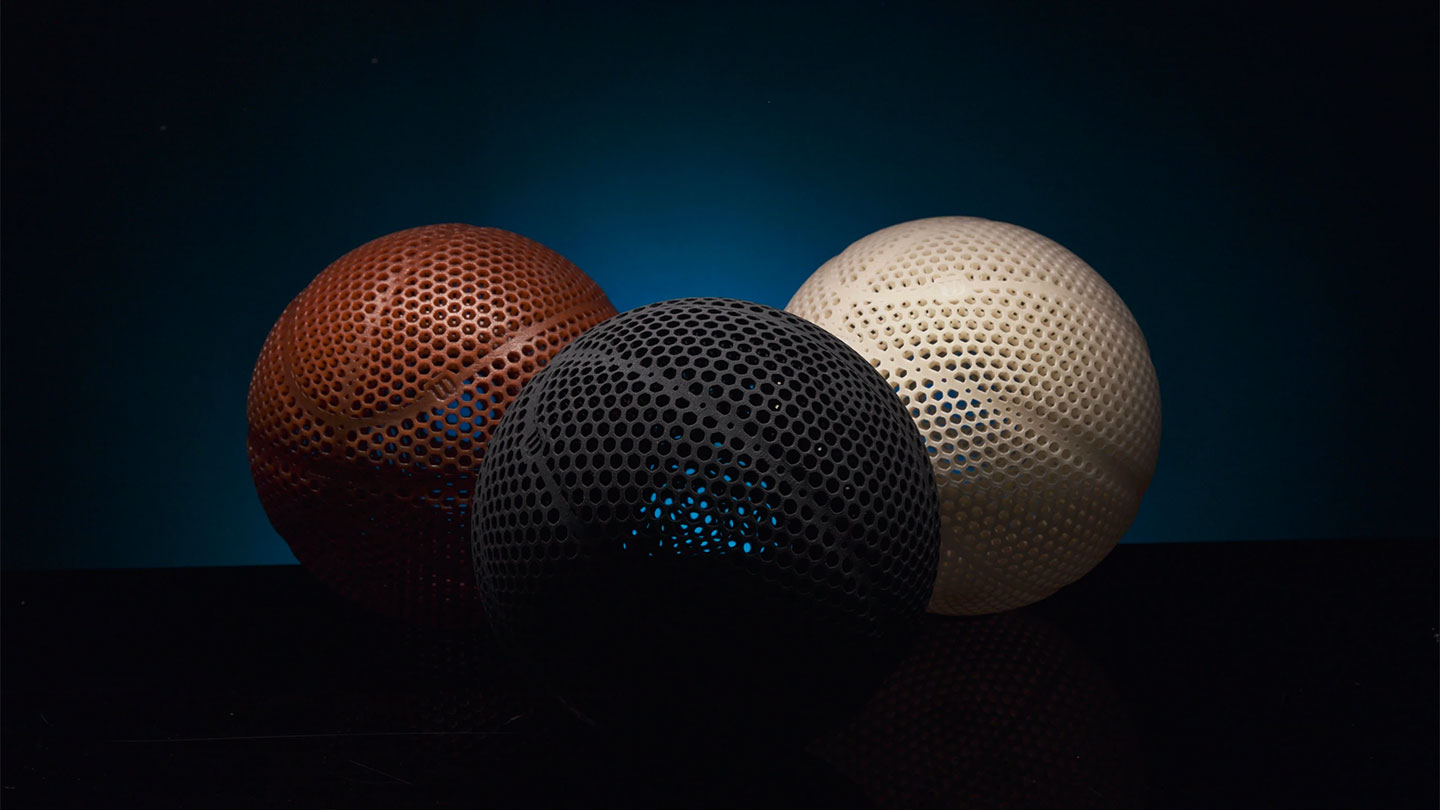

In the past, basketballs were typically crafted from eight or 10 panels of leather or rubber composite, with pressurized air providing their bounce. Wilson Sporting Goods, the manufacturer of the NBA’s official game balls, has introduced a groundbreaking innovation. Their latest creation does away with pressurized air entirely. Instead, this new ball is designed to allow air to flow through it, eliminating the risk of punctures and deflation.

Resembling a honeycomb, the ball’s surface features a lattice of small, hexagonal holes created through cutting-edge 3-D printing technology. Constructed from an elastic polymer, the final product matches the weight of a standard basketball.

Named “Airless Gen 1,” this innovative concept was conceived by Nadine Lippa, Wilson’s basketball R&D manager based in Schiller Park, Ill. The ball is meant to be used without an air pump or needle, offering players instant playability without any preparation. Lippa, holding a PhD in sports and high-performance materials, envisions a sustainable future for this cutting-edge ball.

Embracing a unique design, this new ball not only looks distinct but also feels different due to its use of a special elastic material, as explained by Lippa.

While still undergoing testing, Lippa anticipates that this ball will prove to be more environmentally friendly compared to traditional basketballs. The ball’s single-component construction and local manufacturing potential contribute to a reduced carbon footprint in production and distribution.

One distinguishing characteristic of this exclusive ball is its steep price tag of $2,500, making it a luxury item compared to Wilson’s more affordable offerings, prompting players to ponder its value.

The Physics of Bounce

Over time, a standard basketball loses its bounce as air pressure decreases. Dribbling an old or partially deflated ball may result in insufficient bounce, affecting the gameplay experience.

The bounce of traditional basketballs relies on internal air pressure. As air leaks gradually, the pressure diminishes, compromising the ball’s bounce height. In contrast, the Airless Gen 1, with its 3-D printed polymer lattice, offers a unique solution to this common issue, enhancing the ball’s bounce capability.

Monique McClain, a mechanical engineer specializing in 3-D printed materials at Purdue University, explains that the lattice structure of the Airless Gen 1 enables it to deform, storing and releasing energy similar to springs, which contributes to its superior bounce performance.

The design of the lattice further allows customization of the ball’s bounce intensity, a key feature that sets it apart from conventional basketballs.

Besides improved bounce functionality, the new ball’s design offers a quieter bounce characteristic, as documented in online reviews. This feature, highlighted for its noise reduction during gameplay, presents an appealing aspect for players seeking a more discreet experience.

The choice of materials for the lattice construction plays a crucial role in determining the ball’s bounce and durability. While Wilson has not disclosed the specific material composition, experts suggest a blend of soft and bouncy materials, similar to those found in high-performance sneaker soles, could be utilized in the ball’s production.

The Ultimate Test

Despite its innovative design, the Airless Gen 1 may face challenges in surpassing the performance of traditional basketballs.

According to Patrick Cavanaugh, a research engineer at Purdue University’s Ray Ewry Sports Engineering Center, players’ muscle memory and shooting techniques may require adjustment due to the Airless Gen 1’s altered aerodynamics, potentially leading to changes in flight trajectory and shooting accuracy.

Moreover, Monique McClain suggests that players may notice differences in grip and handling when using the new ball, emphasizing the need for adaptability in gameplay.

While features like a quieter bounce may seem appealing, Jan-Anders Mansson, a materials engineer at Purdue’s Ewry Center, underscores the importance of sound feedback in sports, pointing out the potential impact on players’ rhythm and gameplay experience.

These factors, including the distinct sound profile, could influence not only players but also spectators, affecting the overall ambiance and excitement of the game.

Shaping the Future of Basketball

Despite the challenges, Jan-Anders Mansson expresses admiration for the Airless ball’s innovation and potential for future advancements. He envisions integrating smart sensor technology into the ball to enhance gameplay analysis and performance monitoring.

Nadine Lippa emphasizes the educational value of this pioneering product, highlighting its role in inspiring young minds to explore the intersection of sports and technology and fostering interest in STEAM fields.

While the $2,500 price tag of the designer ball may pose a barrier, DIY enthusiasts have already begun experimenting with 3-D printing their versions. Nevertheless, the authenticity and performance of Wilson’s Airless Gen 1, developed over five years and rigorously tested, remain unparalleled.