During this summer, a team of students from MIT embarked on a journey to the sou …

Particles Derived from Tree Waste Could Help Prevent Fogged Lenses and Windshields

Carlos Changemaker

Cold winters can be especially frustrating for individuals who wear glasses. Almost every time they come indoors, their lenses become fogged up. The same problem occurs when the warm air from a car’s heater hits a cold windshield. Fortunately, a new coating has been developed that could prevent fogging. Its main ingredient: tiny particles made from tree waste.tiny particles made from tree wastes.

When you enter a house from the frosty outdoors, the warm air surrounding you cools down. This leads to the condensation of some of the water vapor in the air into droplets. If you are wearing glasses, these water droplets will stick to the lenses and cause them to fog up, according to Alexander Henn, the developer of the new coating at Aalto University in Espoo, Finland.

The reason why it is difficult to see through glasses covered in water droplets has to do with the shape of the drops, says Monika Österberg, a chemist at Aalto University. Droplets scatter light in all directions, making it impossible to focus on anything. However, if there is a thin film of water, vision remains clear.

Österberg and Henn tackled the issue of fogging by utilizing a renewable waste product called lignin. Lignin is a polymer found in woody plants, providing them with strength and rigidity.

“Here in Finland, we have plenty of trees,” Österberg explains. “Everyone knows that you can use wood for construction, or you can produce pulp for making paper or textiles,” she says. However, most of these processes do not utilize the lignin found in trees, making it a waste product.

Waste lignin appears as a brown powder that resembles cocoa. While it can be used as fuel, Henn states that there are more valuable and environmentally friendly ways to employ it.

Scientists are currently investigating various applications for this abundant resource.

According to Bin Yang, a chemical engineer and microbiologist at Washington State University, there are two main approaches. The first is to produce new chemicals and fuels using lignin, while the second is to create new materials, such as nanoparticles. These nano-sized particles are measured in billionths of a meter.

Prior to focusing on fog prevention, the researchers were already working with lignin nanoparticles. To create these particles, the scientists dissolved lignin powder in a liquid made of organic molecules. When this mixture was poured into water, the lignin particles formed small clusters dispersed throughout the water. Each cluster measured about 100 nanometers in size and had hydrophilic properties, meaning they were attracted to water.

Cutting the fog

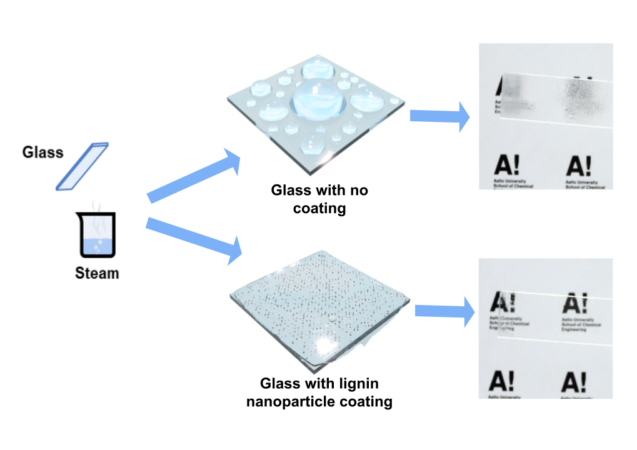

Henn realized that coating glass with these water-loving lignin particles would alter the way the glass surface interacts with water. The nanoparticles would spread out across the glass, creating a thin, continuous layer of water when exposed to droplets. As a result, the lenses would not become foggy.

However, there was a small problem. “You could see the particles,” Henn says. This motivated him to produce smaller lignin particles by modifying the lignin polymers. The new particles, which were less than 50 nanometers in size, were able to go unnoticed when coated onto glass surfaces.

The researchers applied a single layer of the lignin liquid coating to glass and found that it prevented fogging when exposed to steam and temperature changes. Their findings were published on November 1 in the Chemical Engineering Journal.

“Lignin can serve numerous functions,” says Yang. In this case, it creates a highly water-attracting surface that prevents droplet formation. Apart from that, it can be used to produce renewable fuels and has interesting light-absorbing properties. Yang points out that lignin is the second most abundant biomaterial produced by photosynthesis, making it an incredibly valuable renewable resource.

The researchers claim that the coating is cost-effective, and scaling up its production should be relatively simple. Furthermore, the coating could have other applications beyond glasses, potentially improving safety for those who require eye protection but often avoid safety glasses due to foggy lenses. According to Henn, lignin could offer a sustainable solution for this problem.