During this summer, a team of students from MIT embarked on a journey to the sou …

MIT Students Victorious in National Materials Design Competition

Jennifer Livingstone

Two undergraduate students from MIT recently emerged as the winners of the annual ASM Materials Education Foundation’s 2023 Undergraduate Design Competition. The duo, Louise Anderfaas and Darsh Grewal, who are enrolled in Professor Gregory Olson’s class 3.041, worked on a complex project with guidance from MIT postdoc mentor Margianna Tzini. Their outstanding performance earned them the top spot and a prize of $2,000 to share.

“This is probably the highest level of complexity that an undergraduate team has undertaken,” states Olson. Having supervised teams in the competition from both Northwestern University and MIT, he has a good grasp of its difficulty level and is impressed with the work done by Anderfaas and Grewal. He further adds that MIT secured third place in the previous year’s contest by designing a 3D printable alloy specifically for creating Tesla parts.

The ASM Materials Education Foundation serves as the philanthropic arm of ASM International, an organization focused on materials engineering. Its goal is to promote careers in applied science among students and educators.

Super-strong and affordable

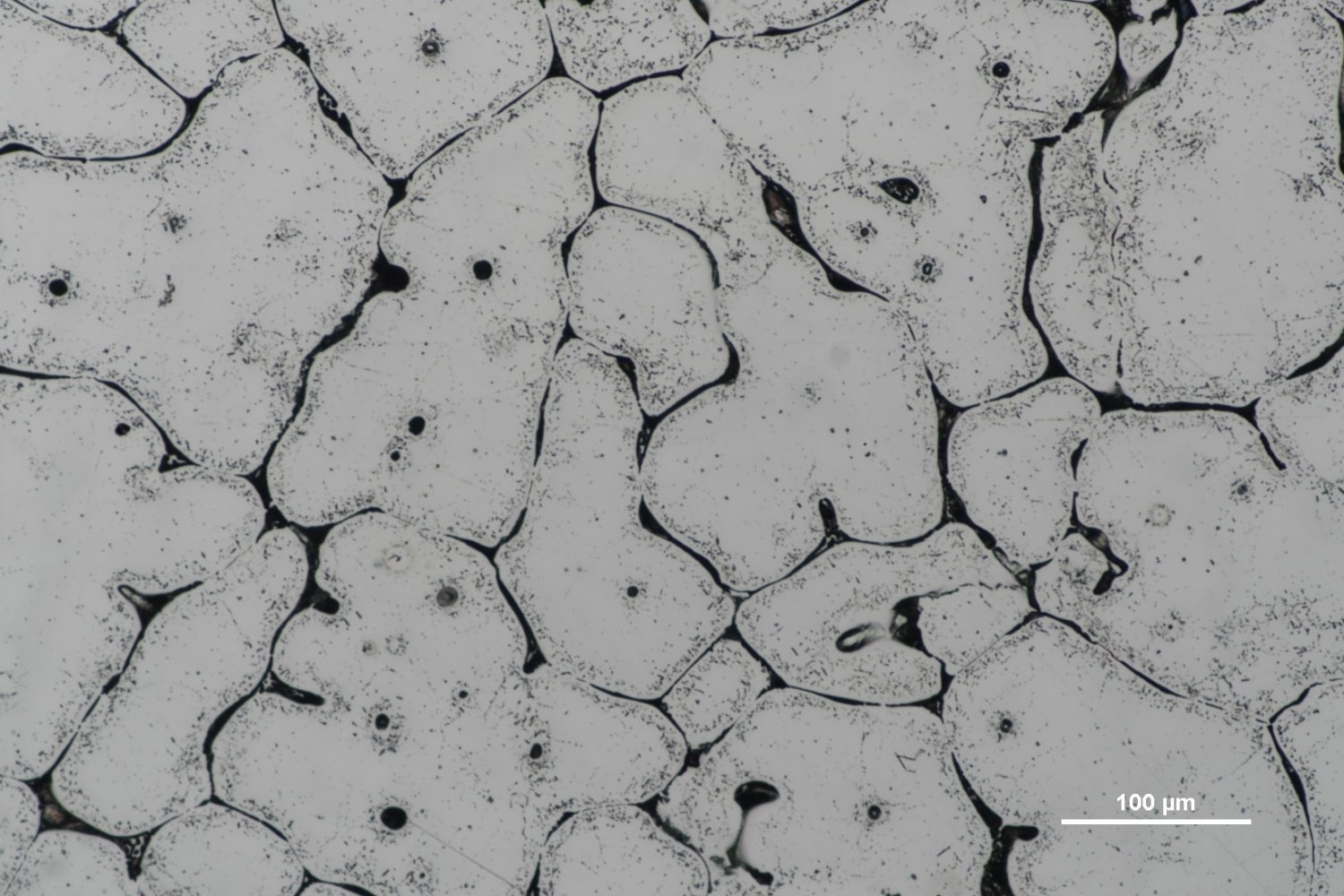

Anderfaas and Grewal’s winning project involved the creation of a 10-centimeter thick, super-strong aluminum plate suitable for various applications, such as planes and cars. The material needed to possess high toughness and resistance against stress corrosion and fractures. The students made a video documenting their step-by-step process, which relied on computer models and calculations to determine the optimal combination of materials and design.

“In order for the material to be used in industrial applications and be cost-effective, we chose conventional processing methods,” explains Anderfaas. Instead of opting for cutting-edge techniques that offer enhanced performance but are more expensive, they utilized traditional manufacturing techniques like cutting and milling. However, due to aircraft specifications, they had to create the product on a large scale, making affordability a crucial factor.

Anderfaas and Grewal, both seniors in the Department of Materials Science and Engineering (DMSE), faced the challenge of integrating all the necessary properties within a three-month timeframe. To develop a highly durable aluminum plate alloy, the students collaborated with the DSO National Laboratory in Singapore, which provided real-life property requirements for the project. They used computational tools based on CALPHAD, a method for calculating material properties, and incorporated density functional theory (DFT) data to optimize the material’s properties with insights into the electronic structure.

The team employed multi-objective optimization to balance the essential variables. Grewal explains how increasing strength comes at a cost, as it may reduce flexibility. Rather than focusing solely on individual properties, they took a holistic approach to address the system as a whole. Both Anderfaas and Grewal credit their understanding of the relationship between structure and properties, which they learned in Olson’s class, for guiding their design process.

The computational design of new materials is a field pioneered by Olson, who teaches the class that prepared Anderfaas and Grewal for the competition. The class combines various core concepts from the MIT materials science curriculum to equip students with the ability to design materials. It focuses on the process-structure-property-performance relationships that dictate material behavior. Olson’s expertise in this area has led to his technology being adopted by major companies like Apple, SpaceX, and Tesla through his startup, QuesTek.

A key aspect of Olson’s class is the incorporation of team projects based on funded graduate research. This allows graduate students and postdocs to serve as coaches to student teams, enabling them to tackle more advanced technical challenges. Tzini played a crucial role in assisting Anderfaas and Grewal by providing specific details about the project and helping them understand its different aspects and connections.

The students had access to databases aligned with the Materials Genome Initiative, a government initiative aimed at accelerating the discovery and development of new materials. These databases contain a wealth of information about the properties, structures, and behaviors of various materials. Olson emphasizes that these databases enable the application of mechanistic knowledge in a quantitative, system-specific manner, and that the class effectively integrates the entire undergraduate materials program curriculum into the design projects.

Anderfaas and Grewal were pleasantly surprised by their victory in the ASM competition. Grewal admits that balancing all the concepts and variables was challenging, but ultimately rewarding. The competition’s second prize went to Purdue University, which improved the process of flattening forged aluminum components, while Michigan Technological University secured third place by reducing boron impurities during the production of cast iron from recycled steel.